Sheet Metal Bending Rules

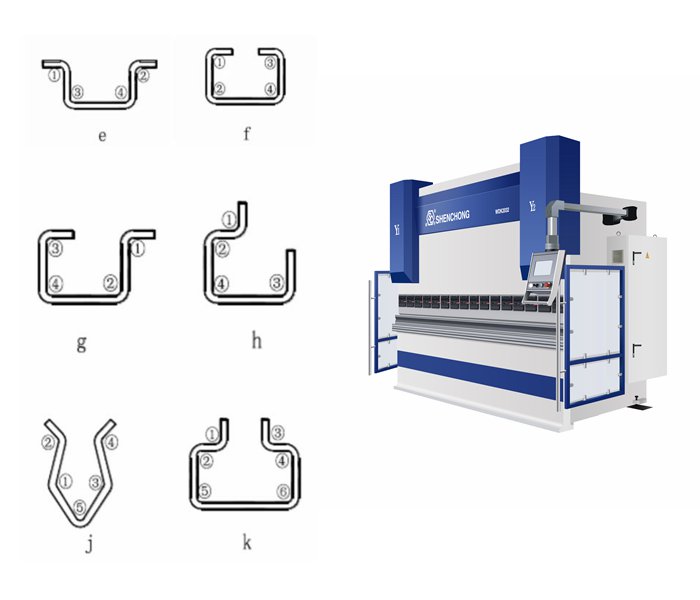

Sheet Metal Bending Rules - The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size.

Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has.

Richtlinien zum Biegen und Umformen von Blechen CNC

If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

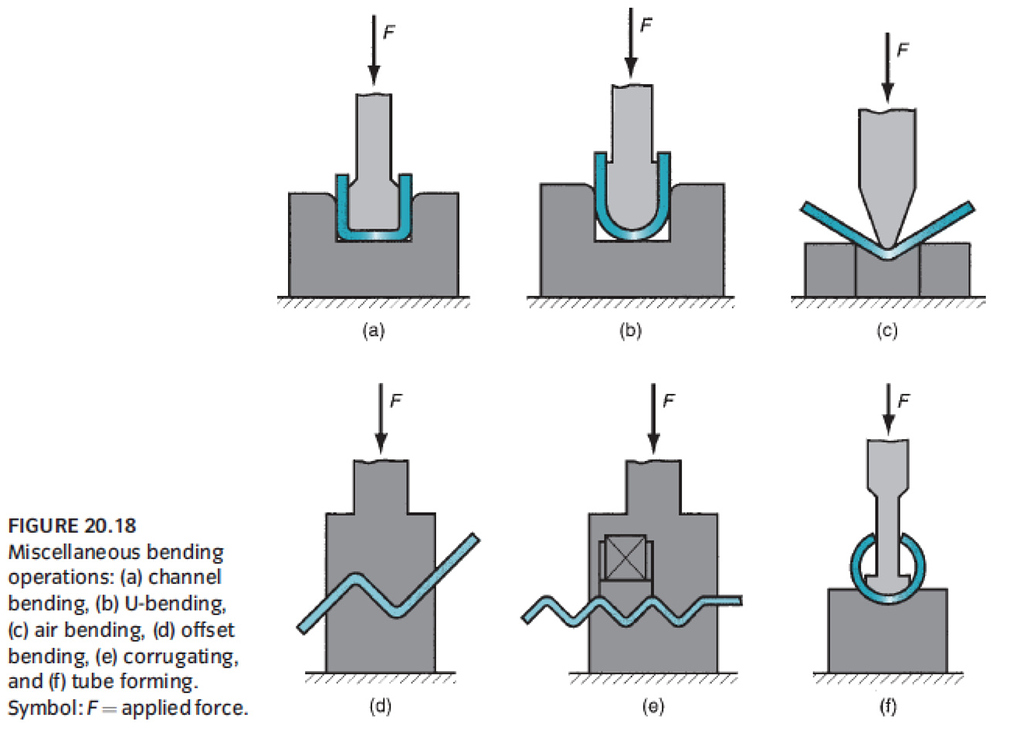

Metal Guidelines Methods of Sheet Metal Bending

Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI

Bending is typically done with a press brake mechanism in a suitable die size. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. If your sheet metal manufacturing designs has.

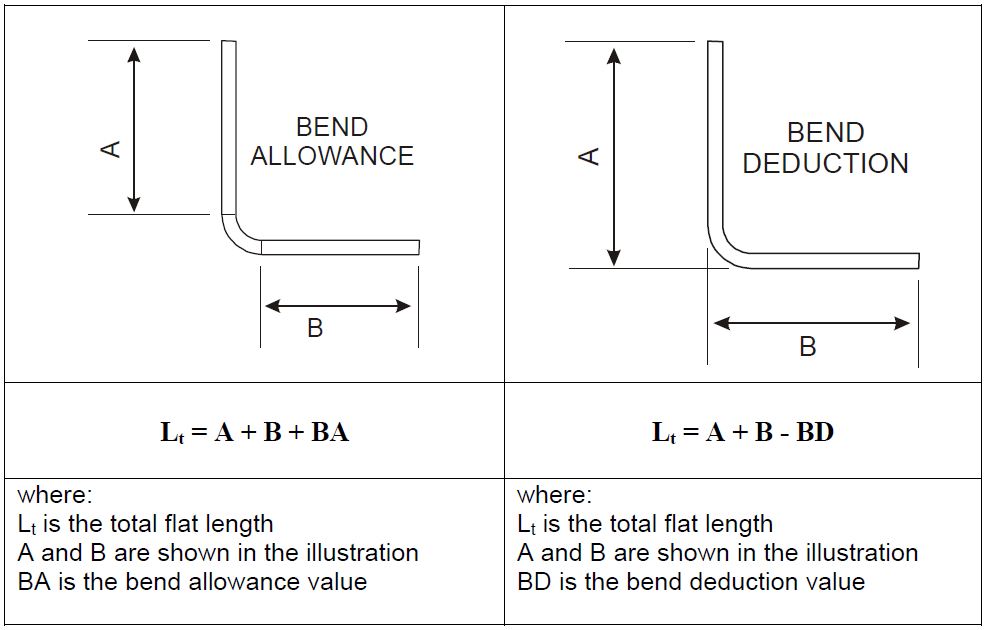

sheet metal bend allowance and deduction

If your sheet metal manufacturing designs has. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Bending is typically done with a press brake mechanism in a suitable die size.

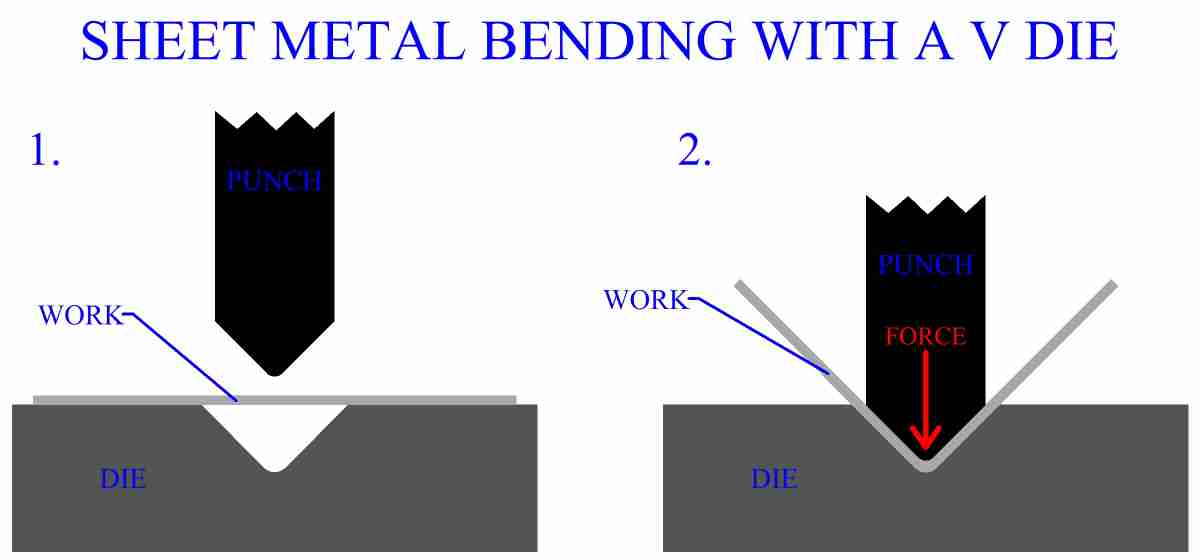

Sheet Metal Bending Techniques

If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

Sheet metalbending MPI Industries Limited

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has.

Common Sheet Metal Fabrication Techniques Meta Fab, Inc.

If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

Sheet Metal Bending Design Guidelines

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size.

The art of sheet metal bending

Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

A Designer’s Guide For Ensuring The Manufacturability Of Sheet Metal

Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

If Your Sheet Metal Manufacturing Designs Has.

Bending is typically done with a press brake mechanism in a suitable die size. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.